In most facilities, problems start where no one can see them: inside panels, behind walls, or within equipment. By the time you notice, it’s already a costly fix.

That’s why many facility managers are turning to thermal imaging. It detects hidden heat patterns that reveal electrical faults, insulation gaps, or leaks before they cause downtime or safety risks.

A professional thermal imaging service gives you clear, actionable data to keep your systems efficient, reliable, and safe, all without interrupting operations.

What is a Thermal Imaging Test?

A thermal imaging test uses infrared cameras to detect heat patterns on equipment, walls, and electrical systems. It shows temperature differences that reveal hidden issues like overloads, leaks, or insulation problems. The process is quick, non-invasive, and helps spot potential failures before they cause damage or downtime.

How Does Thermal Imaging Work?

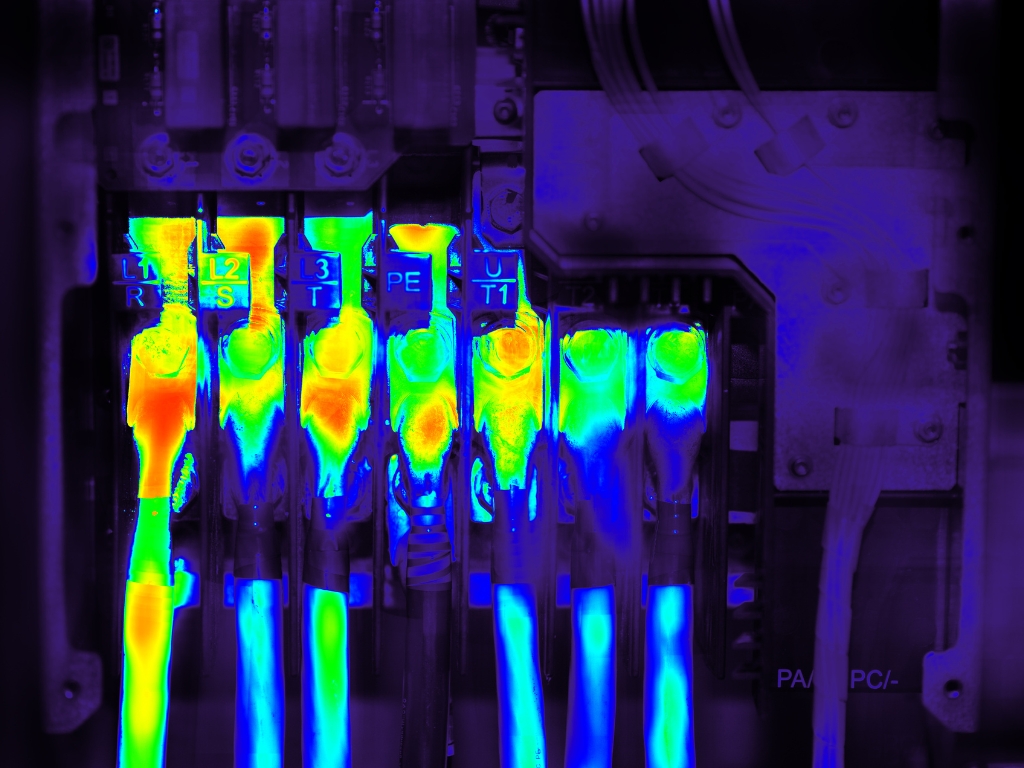

Thermal imaging works by detecting infrared radiation or heat emitted by objects. Every surface gives off heat energy, even if it’s not visible to the naked eye. A thermal camera captures this radiation and converts it into a visual image, where temperature differences appear as varying colors.

Technicians interpret these images to identify abnormal heat patterns. Warmer or cooler areas can signal potential issues like electrical overloads, mechanical wear, or poor insulation.

What is Thermal Imaging Used For?

Thermal imaging has become an essential tool for maintaining commercial buildings and infrastructure. Capturing temperature differences in real time, it gives maintenance teams a clear view of where systems may be underperforming or at risk.

Here are the most common ways thermal imaging services are used across facilities today.

1. Electrical System Inspections

Electrical faults rarely start with sparks; they start with heat. Thermal imaging exposes early signs of loose connections, corroded contacts, and overloaded circuits long before they cause power loss or fire.

By scanning panels and switchgear under normal load, technicians can pinpoint irregular temperature spikes instantly. This data-driven approach reduces downtime, prevents failures, and helps plan maintenance strategically instead of reactively.

2. HVAC System Efficiency

Uneven temperatures and rising energy bills often signal inefficiencies hidden within the HVAC system. Infrared scanning reveals air leaks, poor duct insulation, and blocked vents, which are issues that standard inspections overlook.

With thermal imaging, technicians can confirm whether airflow is balanced and equipment is operating at peak efficiency. The result? More stable comfort levels and measurable savings on energy use.

3. Mechanical Equipment Monitoring

Rotating machinery like pumps and bearings tends to show distress through excess heat. A thermal imaging service makes it easy to monitor that heat signature over time. Subtle changes can indicate friction, misalignment, or failing lubrication.

Instead of waiting for vibration alarms or total failure, maintenance teams can schedule repairs proactively, saving thousands in unplanned downtime and part replacements.

4. Building Envelope and Insulation Checks

Thermal imaging helps facility managers visualize how heat escapes through walls, ceilings, and windows. It pinpoints missing insulation, air leaks, and moisture intrusion without tearing anything apart.

The data allows teams to prioritize repairs that deliver the biggest return in energy savings, improving both sustainability and occupant comfort.

5. Roof Leak Detection

Water trapped under a roof membrane can cause damage long before it’s visible. Thermal imaging detects these wet areas by identifying temperature differences between dry and saturated materials.

For large commercial roofs, this method provides a clear, non-invasive map of where repairs are truly needed. It helps property owners avoid unnecessary tear-offs and extend roof life with targeted maintenance.

6. Data Centers and Electrical Rooms

Even small hotspots in data centers can disrupt uptime or damage sensitive equipment. Thermal imaging identifies overheating servers, cables, and electrical components before they compromise performance.

Continuous or scheduled thermal monitoring ensures balanced cooling and stable temperatures across racks. It’s now a standard preventive measure in mission-critical environments that demand uninterrupted operation.

7. Energy Audits and Sustainability Programs

Thermal imaging gives energy auditors the visual proof they need to identify inefficiencies. By mapping heat loss across mechanical and structural systems, facilities can see exactly where upgrades, like better insulation or equipment tuning, will have the greatest impact.

It also supports sustainability goals by verifying improvements and documenting reduced energy waste over time.

The Role of Thermal Imaging in Predictive Maintenance

Predictive maintenance focuses on preventing failures before they happen, and thermal imaging is one of the most effective tools for making that possible. Here’s how it adds value:

- Tracks subtle temperature changes over time

Regular scans help spot abnormal heat patterns that signal wear, overload, or component stress. - Identifies early warning signs of failure

A bearing, motor, or breaker that runs hotter than normal can be repaired before it breaks down completely. - Supports data-driven maintenance scheduling

Teams can use temperature trends to plan repairs during scheduled downtime instead of reacting to emergencies. - Improves maintenance efficiency

Instead of checking every system manually, technicians can focus only on the equipment showing risk. - Reduces downtime and repair costs

Early detection prevents small issues from turning into major failures — saving both time and money. - Extends equipment lifespan

Maintaining optimal operating temperatures helps machinery perform better and last longer. - Enhances overall safety

Detecting overheating components minimizes the risk of electrical fires and unexpected failures.

How KSB Electric Helps

At KSB Electric, we use thermal imaging services to help facility teams spot issues early and make smarter maintenance decisions. Our certified technicians provide accurate scans, expert insights, and clear solutions, all without interrupting operations.

Here’s what we deliver:

- Precise inspections of electrical, HVAC, and building systems

- Clear reports with images, data, and repair recommendations

- Actionable solutions that prevent failures and reduce downtime

With KSB Electric, you get answers that keep your facility safe, efficient, and reliable.

See What Others Miss with Thermal Imaging

Hidden issues can cost thousands in repairs and downtime, but with the right technology, you can stop problems before they start. KSB Electric’s thermal imaging service helps you detect risks early, protect your assets, and keep your operations running smoothly.

Ready to make your facility safer and more efficient? Contact KSB Electric today to schedule a professional thermal imaging inspection.